Comprehensive Guide to Optimizing Industrial Warehouse Layouts

Understanding the Importance of Warehouse Layout

Optimizing industrial warehouse layouts is crucial for enhancing operational efficiency, reducing costs, and improving overall productivity. An effective layout can streamline processes by minimizing travel time, simplifying inventory management, and ensuring safety. The key lies in careful planning and a thorough understanding of your warehouse operations.

Key Principles of Warehouse Layout Design

Space Utilization

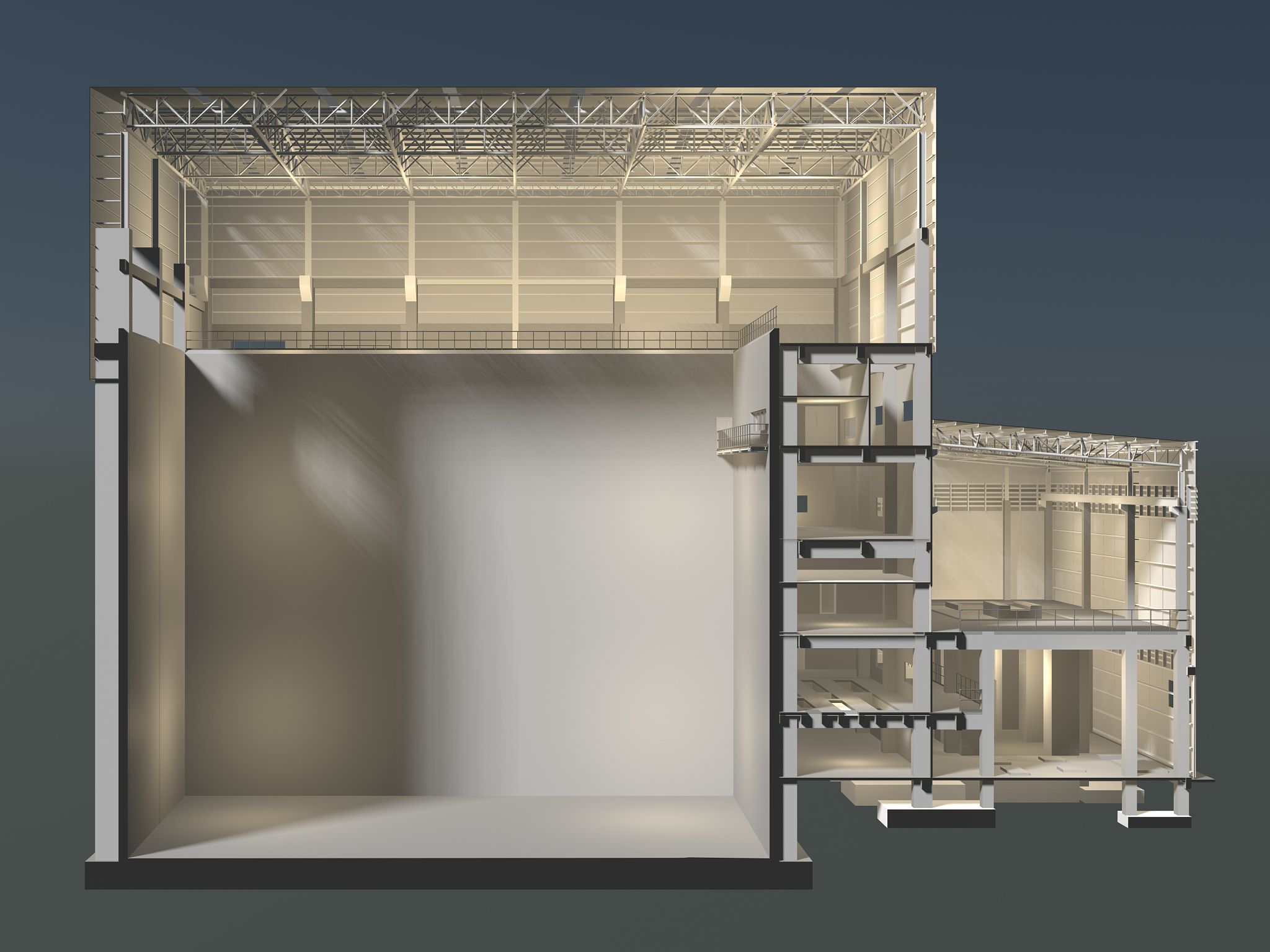

Maximizing space utilization is critical in warehouse layout design. This involves analyzing the available space and organizing storage to accommodate the maximum amount of inventory without compromising accessibility. Consider vertical storage solutions and narrow aisle configurations to make the most of your space.

Workflow Efficiency

The layout should facilitate a smooth and logical flow of goods from receiving to shipping. This can be achieved by strategically placing related operations next to one another, such as positioning packing stations close to the shipping area. Reducing movement and handling times can significantly boost productivity.

Designing for Safety and Compliance

Safety is paramount in warehouse operations. Ensure that your layout complies with safety regulations and provides clear pathways for emergency exits. Incorporate features like proper lighting, signage, and barriers to prevent accidents. Regular training and safety audits can help maintain a safe working environment.

Incorporating Technology and Automation

Integrating technology and automation into your warehouse layout can lead to significant improvements in efficiency. Automated storage and retrieval systems (AS/RS), conveyor belts, and robotic pickers can streamline operations and reduce labor costs. Ensure that your layout accommodates these technologies for seamless integration.

Adapting to Changing Needs

Warehouses are dynamic environments that require flexible layouts to adapt to changing business needs. Factors such as seasonal demand fluctuations, product lines expansion, or alterations in order volumes necessitate layout adjustments. A modular design approach can offer the flexibility needed for these changes.

Implementing Lean Principles

Adopting lean principles in warehouse layout design can help eliminate waste and improve efficiency. This involves continuously assessing and optimizing processes to ensure minimal waste of time, resources, and effort. Techniques such as 5S (Sort, Set in order, Shine, Standardize, Sustain) can be instrumental in maintaining an organized workspace.

Measuring Success and Continuous Improvement

After implementing a new warehouse layout, it's essential to measure its effectiveness through key performance indicators (KPIs). Metrics such as order accuracy, picking efficiency, and inventory turnover can provide insights into the layout's impact. Use these insights to make data-driven decisions for continuous improvement.

Conclusion

Optimizing your industrial warehouse layout is a strategic investment that pays off in increased efficiency, reduced costs, and improved safety. By understanding key principles, leveraging technology, and embracing flexibility, you can create a well-optimized space that supports your business's growth and success.