Common Mistakes in Industrial Warehouse Design and How to Avoid Them

Introduction to Industrial Warehouse Design

Designing an industrial warehouse is a complex task that requires careful planning and execution. A well-designed warehouse can significantly enhance operational efficiency, while a poorly designed one can lead to costly errors and bottlenecks. This blog post explores some common mistakes in industrial warehouse design and offers insights on how to avoid them.

Failing to Plan for Future Growth

One of the most common mistakes in warehouse design is neglecting to consider future growth. Businesses often focus on current needs without anticipating future expansion. It's crucial to design a warehouse with flexibility in mind, allowing for scalability and adaptability as the business grows. This might include modular shelving systems or reserving space for additional storage.

How to Avoid This Mistake

To avoid this pitfall, conduct a thorough analysis of your business growth projections. Collaborate with stakeholders to understand potential changes in product lines, inventory levels, and order volumes. Incorporating these insights into the design will help ensure the warehouse remains functional and efficient over time.

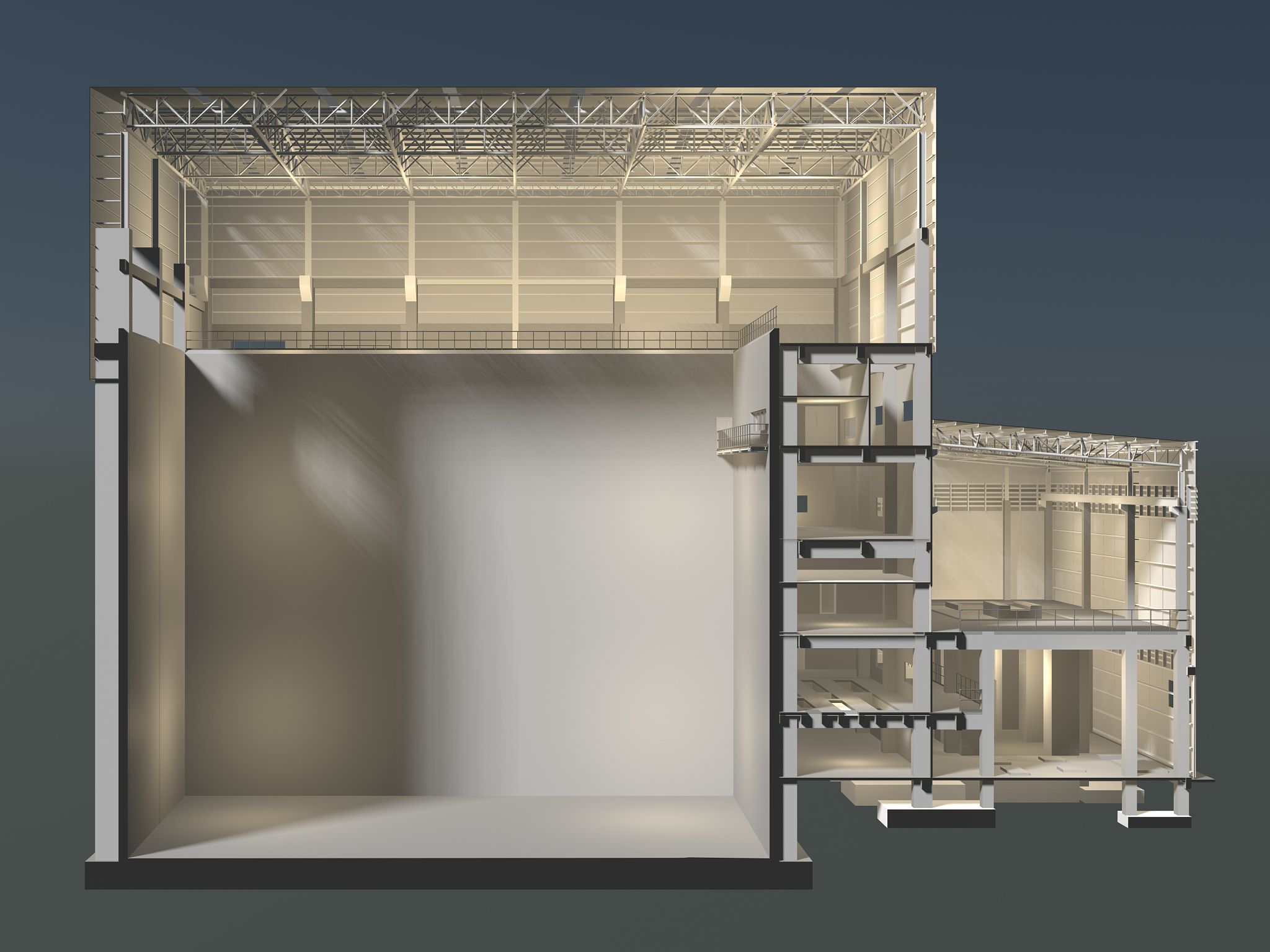

Inefficient Layout Design

An inefficient layout can lead to increased travel time, poor space utilization, and reduced productivity. Many warehouses fall into the trap of not optimizing the flow of goods, which can be detrimental to operations. An effective layout should minimize unnecessary movement and ensure a smooth flow of materials from receiving to shipping.

Strategies for an Efficient Layout

Consider implementing a layout that follows the principles of lean manufacturing. This might include using a U-shaped or L-shaped design to streamline operations. Position frequently accessed items closer to picking areas and allocate space based on inventory turnover rates. Utilizing technology such as warehouse management systems can also aid in optimizing layout efficiency.

Ignoring Safety Regulations

Safety is a critical aspect of warehouse design that should never be overlooked. Failing to comply with safety regulations can lead to accidents, injuries, and even legal issues. Common safety oversights include inadequate signage, poor lighting, and insufficient emergency exits.

Ensuring Compliance and Safety

Start by familiarizing yourself with local and international safety standards applicable to your industry. Ensure that all safety measures are integrated into the design from the outset. Regularly update safety protocols and provide ongoing training for staff to maintain a safe working environment.

Poor Environmental Considerations

As sustainability becomes increasingly important, neglecting environmental factors in warehouse design is a significant oversight. Energy efficiency, waste management, and environmentally friendly materials should be considered during the design phase.

Incorporating Sustainability

Implement energy-efficient lighting systems such as LED lights, which can reduce energy costs considerably. Consider installing solar panels or other renewable energy sources. Incorporate recycling programs and use sustainable materials whenever possible to minimize environmental impact.